RFID techno-

logy

Facilitates railway maintenance

Component detection and tracking

RFID (English radio-frequency identification, “Identification with the help of electromagnetic waves”) denotes a technology for transmitter-receiver systems for the automatic and contactless identification and localisation of objects and life forms with radio waves (Wikipedia).

In the VGF Central Tram Workshop (StZw), there’s plenty of bonding going on: All time-restricted components that are relevant to tram construction and the operation regulations of a vehicle are equipped with a “tag”. With the help of such a tag, the components – such as car bodies, bogies, axles, air-conditioning systems and power converters – are automatically assigned to the vehicle in which they are installed. This saves the time-consuming transcription of serial numbers with subsequent transfer to the zedas maintenance and planning system (IPS). It also optimises component tracking for weak-point analyses and improves the preservation of warranty claims asserted against external suppliers.

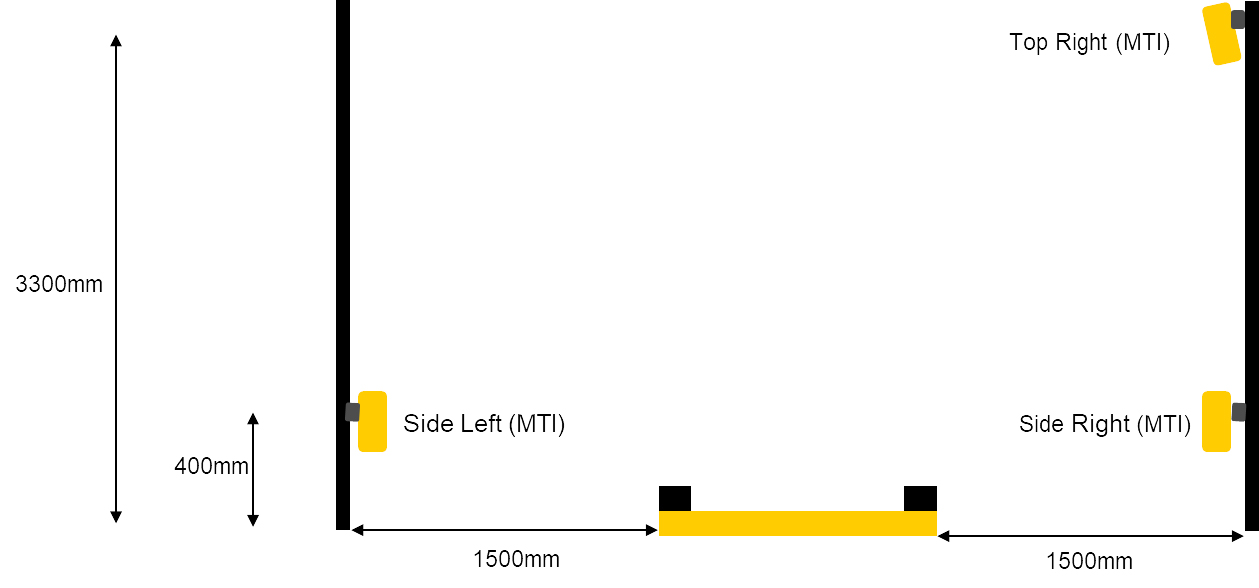

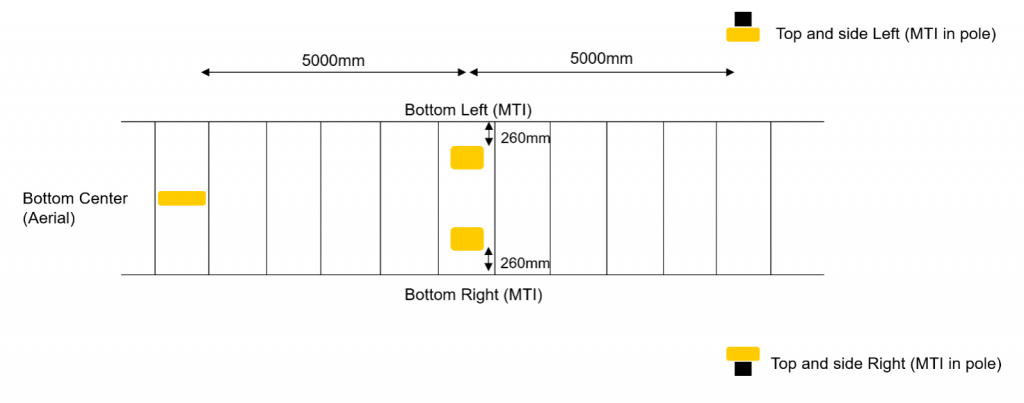

The respective serial number is transmitted to the electronic asset management system together with the date, time and mileage. This data transmission takes place at RFI portals, which will be located at several VGF sites in the future. The first RFID portal – which consists of two masts with antennas, as well as additional antennas located directly in the track bed – is in operation at the depot in Gutleut. Others will follow in the Stadtbahn Central Workshop, in “Betriebshof Ost”, and then in the Heddernheim depot. In order to exclude reading errors and thus the transmission of false data, a transmission logic is defined: All captured data of the RFID tags must match in three consecutive readouts before they are transmitted to the IPS system zedas. A readout of the RFID tags is possible up to an overrun speed of 60 km/h.

Currently, about 5 % of the components in our “S” and “U5” cars are tagged. The new technology is to be tested under real conditions by the summer of 2021, after which it will be launched in an extensive test operation phase.

An expansion of the technology to other areas and vehicle parts is being considered.

Social Networks

© Stadtwerke Verkehrsgesellschaft

Frankfurt am Main mbH