Predictive Maintenance

The term “Predictive maintenance” refers to the preventive maintenance of infrastructure facilities, ...

… be it tracks, switches, vehicles or – as in this case – the overhead line.

Contact wire, which supplies power to the underground trains and trams across a total of 19 lines, hangs along 193.3 kilometres of the tram network and along 67.7 kilometres of the underground, 44 kilometres of which are in tunnels. 5,400 masts and 1,232 wall mountings keep the system in the air. In future, VGF intends to use a digital measuring procedure to check and maintain this system of masts and other fixings, as well as contact and tension wires. The advantage: instances of damage – for example, corroded masts that have gone unnoticed, “sagging” contact wires – are meant to be detected before damage actually occurs, which would otherwise result in high costs and lead to operational disruption, which in turn would ultimately also affect passengers.

The background to the digitalisation of maintenance is climate change and the mobility revolution, in the course of which public transport is to be expanded, which will translate into narrower travel intervals and 24-hour operation on the lines. This means a higher infrastructure load, which in turn must result in modern and efficient maintenance.

Preventive maintenance of the overhead line is part of a holistic infrastructure project, which also includes the tracks and switches.

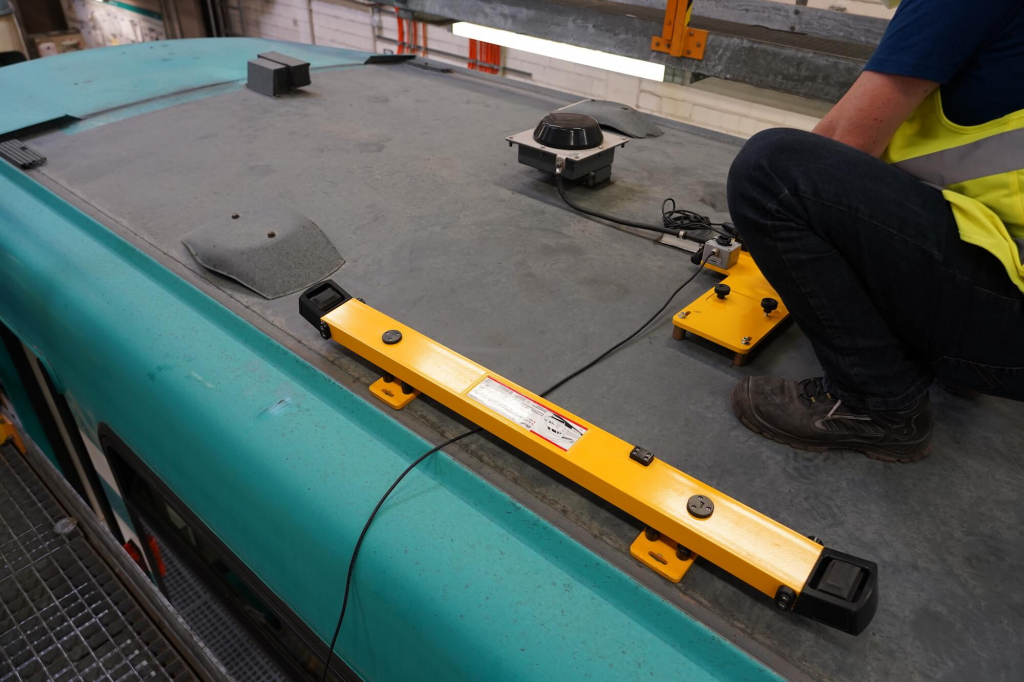

VGF is testing the measurement of the height and lateral position of the overhead line using ultrasonic sensors that are deployed in a dedicated measurement train. Corresponding devices are mounted on the roof of the carriage and supply data to the computer in the interior. The distance sensor, which is installed in the vehicle itself, supplies the system with the correct position of the train in the network. Deviations or anomalies are detected by comparing target and actual values. During the journey, the employees also have the chance to visually check the travelled and tested overhead line section thanks to a camera. The digitalisation associated with this new procedure is intended to replace the manual inspection of the overhead contact line systems – covering large distances and conducting individual measurements – and thus make the process faster and more efficient.

The tests have been taking place since the summer of 2021 with an old tramcar. The near 50-year-old type “Pt” Car No. 2050 is enjoying its fourth calling as a measurement train: as number 664, it was used for many years as a tram, then as a driving school car and most recently as the “SchneeschieBÄR”, the winter deployment vehicle of VGF. As such, it has recently been fitted with a new contact wire wetting system on the pantograph to prevent the overhead line from icing up.

The measurement train – the result of an internal ideas competition – covers more than just the overhead line and is, therefore, a cross-departmental joint project. Its use is intended to automate and digitalise track maintenance as a whole by having the train record five relevant measured variables of the infrastructure during the journey. In addition to the contact wire system, track measurement, signal strength measurement, condition monitoring and GPS tracking have been planned initially. An extension of this list is possible. In the long term, it should be possible to evaluate the measured variables via ZEDAS and GEOTrams. The deployment of the train, presumably also a “Pt” car in its ultimate state, is planned from 2022 onwards.

Social Networks

© Stadtwerke Verkehrsgesellschaft

Frankfurt am Main mbH